Analysis

AQRC measures the concentrations of chemical elements in samples using energy dispersive X-ray fluorescence (XRF). We specialize in measuring airborne particulate matter sampled on filters but can also analyze liquid, solid or powder samples.

Our laboratory is equipped with five PANalytical Epsilon 5 XRF analyzers. Each analyzer can be programmed to use up to 15 secondary excitation targets, allowing the analysis to be customized to provide optimal sensitivity for the elements of interest with comprehensive coverage of the periodic table. Learn more about Epsilon products here.

Calibration

AQRC researchers have developed improved certified reference materials for calibration, calibration verification and QC of XRF analyzers utilized for analysis of airborne particulate matter (PM) samples.

Our system can provide pure, stoichiometric reference materials on various filter materials (and different filter sizes) and is useful for any air pollution sampling projects that collect PM on filters for analysis by XRF. Having calibration standards prepared on the same filter material as PM samples collected in the field mimics the filter matrix effects of the samples and thus provides a more reliable calibration.

Improved XRF calibration standards

The AQRC/Air Quality Research Center specializes in elemental analysis of airborne particulate matter (PM) collected on PTFE filters. Energy dispersive XRF is commonly used technique to analyze PM samples, but commercially available calibration standards are not ideal for this application. AQRC’s new system for developing calibration and QC reference materials fills this gap by using in the lab the same sampling techniques that are used in the field for air quality sampling. Our new certified reference materials provide a more tailored calibration approach for air pollution sampling projects that collect PM on filters for analysis by XRF.

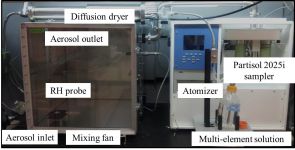

AQRC’s system for production of reference materials consists of equipment that generates particles, a mixing chamber, and an aerosol sampling device for PM.

The system can provide pure, stoichiometric reference materials on various filter materials. Having calibration standards prepared on the same filter material as PM samples collected in the field mimics the filter matrix effects of the samples and thus provides a more reliable calibration.

Available single element (SE) certified reference materials prepared in our laboratory: Sodium (Na), Aluminum (Al), Silicon (Si), Sulfur (S), Chlorine (Cl), Potassium (K), Titanium (Ti), Iron (Fe), Zinc (Zn) and Lead (Pb), with loadings starting at 0.5 µg/cm2 on 47 mm filters

SE Reference materials under development (work in progress): Copper (Cu), Phosphorus (P), Magnesium (Mg)

SE Reference materials planned to be developed by 2017: Calcium (Ca), Vanadium (V), Chromium (Cr)

We have verified our single (or double) reference materials using multiple analytical techniques and can certify them by gravimetric measurement.

Our calibration standards have a number of advantages over those that are commercially available.

- They are composed of airborne PM of the same size as ambient airborne particles. Other commercially available calibration standards are thin films created by chemical vapor deposition.

- AQRC’s calibration standards can be developed using compounds found in ambient PM. Commercially available standards are often developed using compounds that are not observed in ambient PM.

- The mass ranges of the AQRC calibration standards are within the relevant ranges of elements in ambient PM samples. Commercial calibration standards are generally in much higher ranges.

- AQRC uses the same filters—for example, PTFE (Teflon®) filters—as used in ambient sampling. Commercial standards generally use substrates that are not commonly used in ambient sampling.

We also developed Multi-element reference materials (ME), currently with 28 elements, mimicking atmospheric PM composition and spanning range. Due to complex composition of these reference materials, we cannot provide gravimetrically certified loadings; instead, we developed a methodology to assign the reference loadings.

The MEs can serve as quality control and calibration verification reference materials to:

- check the performance of XRF analyzers, which are typically calibrated using single compound standards.

- provide the insight on the performance of the software to resolve many inter-elemental interferences.

For information about development of reference standards for specific purposes, contact Nicole Hyslop.